Accessori per contenitori

Accessori per contenitori

-

Prodotti

Prodotti Contenitori e manopole

Moderni contenitori in plastica, contenitori in allumino e manopole per i più diversi settori: contenitori per applicazioni portatili, a muro, da scrivania, per guida DIN, ecc. Convincetevi di persona!

Contenitori in plastica Innovativi contenitori in plastica per l'industria elettrica ed elettronica

Contenitori in plastica Innovativi contenitori in plastica per l'industria elettrica ed elettronicaPer un design moderno degli apparecchi. Il nostro sito offre un panorama generale che vi permette di scegliere la soluzione più adatta dal nostro ampio assortimento.

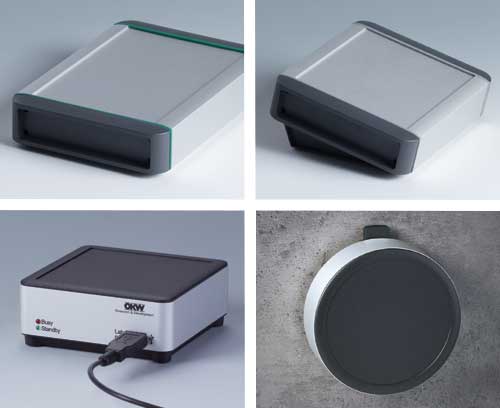

Contenitori in alluminio Contenitori di alta qualità in profilato di alluminio in un mix raffinato con materiale plastico

Contenitori in alluminio Contenitori di alta qualità in profilato di alluminio in un mix raffinato con materiale plasticoPer proteggere in modo affidabile i vostri dispositivi elettronici. Profilati di alluminio in lunghezze speciali su richiesta.

Manopole Ampio programma di manopole: design ergonomico, classico e moderno

Manopole Ampio programma di manopole: design ergonomico, classico e modernoDi provata validità per potenziometri rotanti con estremità dell'albero arrotondate e appiattite secondo DIN 41591 ovvero di 6/4,6 mm.

-

Customizzazioni

Customizzazioni Vi forniamo i contenitori pronti per il montaggio in base alle vostre richieste ed esigenze

Non esitate a dirci cosa vi serve per il vostro prodotto perfettamente individuale. I nostri contenitori e le nostre manopole vengono quindi modificati e personalizzati in modo corrispondente. Qui trovate una panoramica delle nostre prestazioni.

Lavorazione meccanica Realizziamo per voi lavorazioni individuali in modo rapido e affidabile

Lavorazione meccanica Realizziamo per voi lavorazioni individuali in modo rapido e affidabileFresatura di spazi / realizzazione di aperture per interfacce, display, elementi di comando nonché ingressi e uscite di cavi, fori filettati, incavi per pellicole ecc.

Verniciatura Eseguiamo la verniciatura di contenitori e manopole per superfici di grande validità estetica e funzionale

Verniciatura Eseguiamo la verniciatura di contenitori e manopole per superfici di grande validità estetica e funzionalePotete scegliere i vostri colori aziendali o una vernice protettiva per requisiti speciali, per es. la vernice ESD.

Stampa Eseguiamo la stampa serigrafica/a tampone e digitale di contenitori, placche frontali e manopole

Stampa Eseguiamo la stampa serigrafica/a tampone e digitale di contenitori, placche frontali e manopoleStampa di logo, testo e grafica nei colori desiderati.

Marcatura laser La marcatura laser viene offerta per numerosi contenitori e componenti del programma standard

Marcatura laser La marcatura laser viene offerta per numerosi contenitori e componenti del programma standardPer la personalizzazione tramite scritte, indicazioni e marcature: logo, testo e grafica.

Pellicole decorative Eseguiamo la stampa digitale di pellicole decorative per scritte su contenitori in qualità fotografica

Pellicole decorative Eseguiamo la stampa digitale di pellicole decorative per scritte su contenitori in qualità fotograficaPellicole con/senza rilievo per funzioni dei tasti, finestre display/LED, codici a barre, ecc.

Materiale speciale Realizziamo i contenitori standard e le manopole in materiale plastico anche nei vostri colori

Materiale speciale Realizziamo i contenitori standard e le manopole in materiale plastico anche nei vostri coloriDefinizione individuale del colore in base a campione, RAL, Pantone ecc.

Protezione CEM In numerosi contenitori in materiale plastico applichiamo un rivestimento interno a protezione dalle radiazioni elettromagnetiche

Protezione CEM In numerosi contenitori in materiale plastico applichiamo un rivestimento interno a protezione dalle radiazioni elettromagneticheSicurezza e affidabilità grazie a CEM in base alle applicazioni.

Confezionamento / montaggio Eseguiamo lavori di montaggio per il completamento di gruppi ovvero apparecchi

Confezionamento / montaggio Eseguiamo lavori di montaggio per il completamento di gruppi ovvero apparecchiMontaggio di accessori per contenitori, incollaggio di pellicole decorative e lastre per display, assemblaggio di gruppi, montaggio personalizzato dei componenti con supporti distanziali, punti di fissaggio, ecc.

Soluzioni dei nostri partner Cooperiamo con partner dalle prestazioni convincenti

Soluzioni dei nostri partner Cooperiamo con partner dalle prestazioni convincentiGrazie alle cooperazioni in fatto di sistemi di immissione e di alimentazione di energia/corrente siamo in grado di offrirvi contenitori su misura come soluzioni complete.

-

Applicazioni

- Medicina / Laboratorio / Wellness

- Metrologia / Tecnica di regolazione / Automazione

- Costruzioni meccaniche / Impiantistica

- Tecnologia dei veicoli / Macchine edili / Settore militare / Aeronautica

- Riscaldamento / Condizionamento / Ambiente

- Tecnica di sicurezza / Gestione di impianti tecnici di edifici

- Comunicazione

- Industria mineraria / Gas / Petrolio

Applicazioni Profondo know-how in fatto di applicazioniGli esempi di applicazioni dei clienti mostrano le svariate possibilità per l'impiego dei nostri contenitori e delle nostre manopole. Scegliete il campo di impiego per il quale desiderate ulteriori informazioni.

Medicina / Laboratorio / Wellness Uomo ed ergonomia

Medicina / Laboratorio / Wellness Uomo ed ergonomiaOKW mira a soluzioni innovative e di alta qualità dalle forme ergonomiche che infondono fiducia.

Metrologia / Tecnica di regolazione / Automazione Uomo e precisione

Metrologia / Tecnica di regolazione / Automazione Uomo e precisioneLe soluzioni di OKW garantiscono un alto livello di comfort di comando e di sicurezza nell'uso quotidiano.

Costruzioni meccaniche / Impiantistica Uomo e produzione

Costruzioni meccaniche / Impiantistica Uomo e produzioneLe soluzioni di OKW permettono facilità di comando e di lettura e si distinguono per la grande affidabilità.

Tecnologia dei veicoli / Macchine edili / Settore militare / Aeronautica Uomo e mobilità

Tecnologia dei veicoli / Macchine edili / Settore militare / Aeronautica Uomo e mobilitàI contenitori e le manopole di OKW resistono anche alle sollecitazioni più intense grazie alla struttura robusta e ai materiali di alta qualità utilizzati.

Riscaldamento / Condizionamento / Ambiente Uomo ed efficienza

Riscaldamento / Condizionamento / Ambiente Uomo ed efficienzaOKW sviluppa soluzioni in base alle esigenze in modo che i loro utilizzatori possano sfruttarle a lungo.

Tecnica di sicurezza / Gestione di impianti tecnici di edifici Uomo e tecnica

Tecnica di sicurezza / Gestione di impianti tecnici di edifici Uomo e tecnicaOKW ha un ruolo di pioniere nello sviluppo delle soluzioni più moderne per sostenere il progresso delle tecnologie smart.

Comunicazione Uomo ed informazione

Comunicazione Uomo ed informazioneOKW pone nuove pietre miliari per permettervi di strutturare in modo ottimale i vostri processi di informazione e di comunicazione.

Industria mineraria / Gas / Petrolio Uomo e materie prime

Industria mineraria / Gas / Petrolio Uomo e materie primeAmbienti difficili - OKW ha le soluzioni per un elevato standard di qualità a protezione dei vostri componenti elettronici.

-

News

News

Novità di OKW

Scoprite i nuovi prodotti e le innovazioni di OKW e leggete i comunicati stampa attuali dell'azienda.

NewsComunicati stampa

NewsComunicati stampaPer essere aggiornati

Qui sono disponibili i comunicati e le immagini per la stampa.

Fiere ed esposizioni

Fiere ed esposizioniIncontri sul posto

Calendario attuale di fiere e manifestazioni internazionali a cui partecipano OKW e i partner di distribuzione. Appuntamenti da non perdere!

-

Informazioni

Come posso ricevere un campione o un'offerta?Con il simbolo del carrello potete inserire prodotti nel carrello e poi richiedere un campione e/o un'offerta. Per ulteriori informazioni si veda qui.

Informazioni specifiche direttamente dagli esperti

Informazioni specifiche direttamente dagli espertiSpiegazioni dettagliate sulla scelta dei materiali, sugli standard internazionali come per es. i gradi di protezione, i test di infiammabilità, le direttive in materia ambientale ecc.

Istruzioni di montaggio, certificati, rivista clienti INSIDE e pubblicazioni di stampa specializzata

Istruzioni di montaggio, certificati, rivista clienti INSIDE e pubblicazioni di stampa specializzataQui potete scaricare le informazioni desiderate.

PDF e AutoCAD DWF

PDF e AutoCAD DWFAvvertenze di utilizzo e link ai siti dei produttori per scaricare i programmi di visualizzazione.

-

Società

Tradizione e modernitàOKW Gehäusesysteme è un'azienda tedesca con sede a Buchen/Odenwald. Una breve sintesi dei fatti più importanti sulla nostra attività, sulla nostra gamma di prodotti e sulla storia della nostra azienda.

Filiale OKW Svizzera

Filiale OKW SvizzeraOkatronic AG è l'affiliata svizzera di OKW Gehäusesysteme di Buchen in Germania. La nostra ditta è stata fondata a Härkingen nel 1996.

OKW nel mondo

OKW nel mondoPer trovare i partner di OKW a cui rivolgersi nelle rispettive zone.

Affiliate presenti in 8 paesi in 4 continenti e partner di distribuzione pluriennali in tutto il mondo sono a vostra disposizione sul posto.

Assumere responsabilità

Assumere responsabilitàI nostri prodotti rispondono ai requisiti delle direttive e dei regolamenti in materia ambientale come REACH, RoHS, WEEE ecc.

La tutela dei vostri dati personali è importante per noi e desideriamo che vi sentiate sicuri quando visitate il nostro sito web.

La tutela dei vostri dati personali è importante per noi e desideriamo che vi sentiate sicuri quando visitate il nostro sito web.Ecco una breve panoramica sul tema della tutela dei dai.

Note legali

Note legaliNote legali di Odenwälder Kunststoffwerke Gehäusesysteme GmbH a Buchen.

-

Contatto

Contattarci è facilissimoLa vostra e-mail viene inoltrata direttamente all'indirizzo competente per la relativa regione.

In alternativa potete anche compilare la lista dei desideri e inviare una richiesta utilizzando il simbolo del "Carrello".